Soft robot arms

Context

Avner Peled's thesis consists on the development of a telepresence soft robot. For this project, he decided to prototype the robot part by part; and recurred to me to assist with the cad modelling of the hand actuators.

The hand actuator consists of a silicone hand shape, which could host an electronic board at the palm. The main feature of this hand, is that when pressure is applied to the main chamber, it would bend as a soft articulation. The mechanical actuation is based on the information offered by soft robotics toolkit.

Process

After previous experiences using 3d printed models for the molds, it was decided to produce this mold in CNC instead, because the CNC can produce soft edges which make the de-molding easier.

There was a long discussion and design process, as the constraints were challenging:

- the molds need to be produced on CNC,

- it has to be possible to extract the shapes from the molds,

- the production process is two-step (inner chamber and outer chamber);

- the chamber is hollow,

- it needs to be able to host a pressure sensing circuit at the palm,

- hence, it needs to conduct six lines for SPI communication with the circuit.

- The mold also needed to handle bubbles, which often appear while injecting the silicon.

- In addition, the thickness of the inflatable chamber is 1mm, leaving very little tolerance.

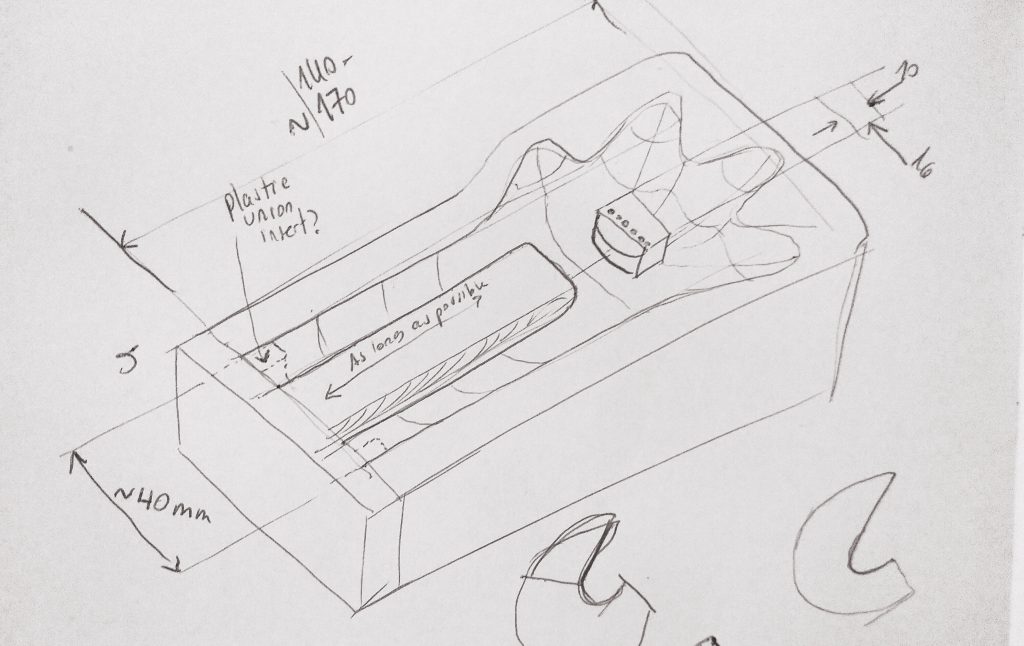

The design was mainly thought out through sketching and discussion with Avner, whom had already experimented with silicon casting. The resulting design strategically utilizes the spacer for the electronics as a guide for the inner rod, which makes the space for the air chamber. This model also makes strategic use of a flat face which allows using a transparent acrylic. This reduced machining time and provides a see-through.

The final model was generated using Autodesk's Fusion 360. The design is adaptable to different parameters, except for the hand section; because it was modeled using NURBS.

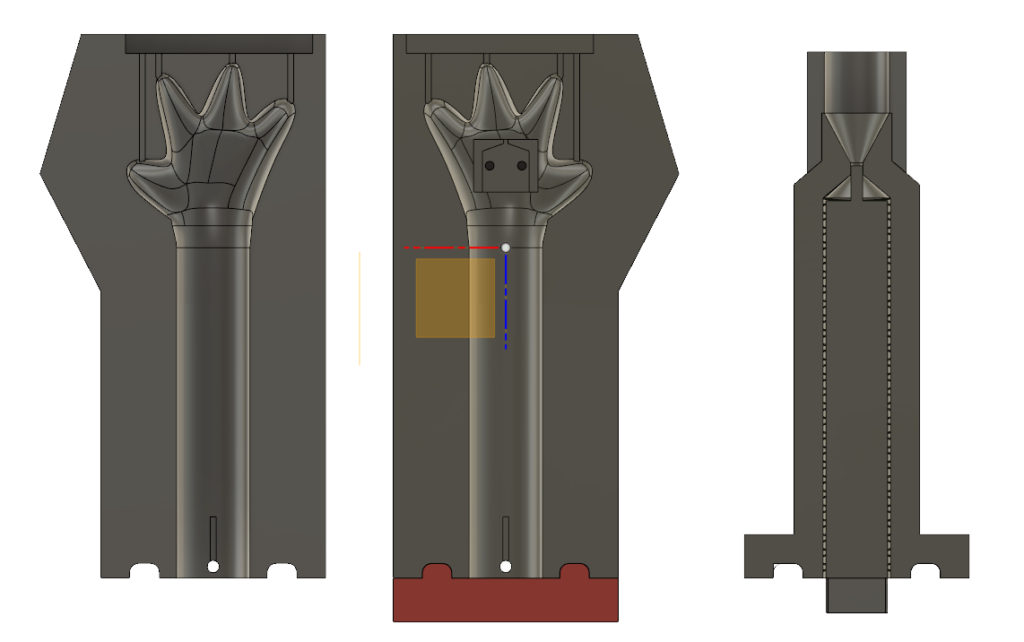

The two step cast: the first step at the right, and the second step (left and right hand molds) at the left.

Result

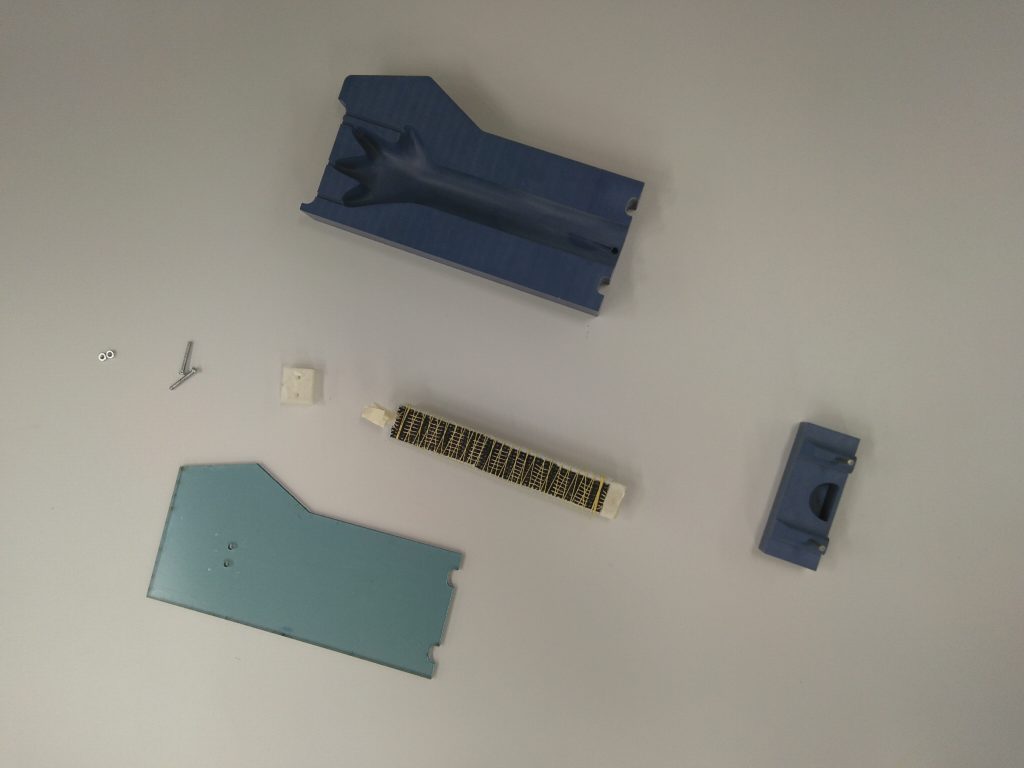

Mold, step 1

Mold, Step 2

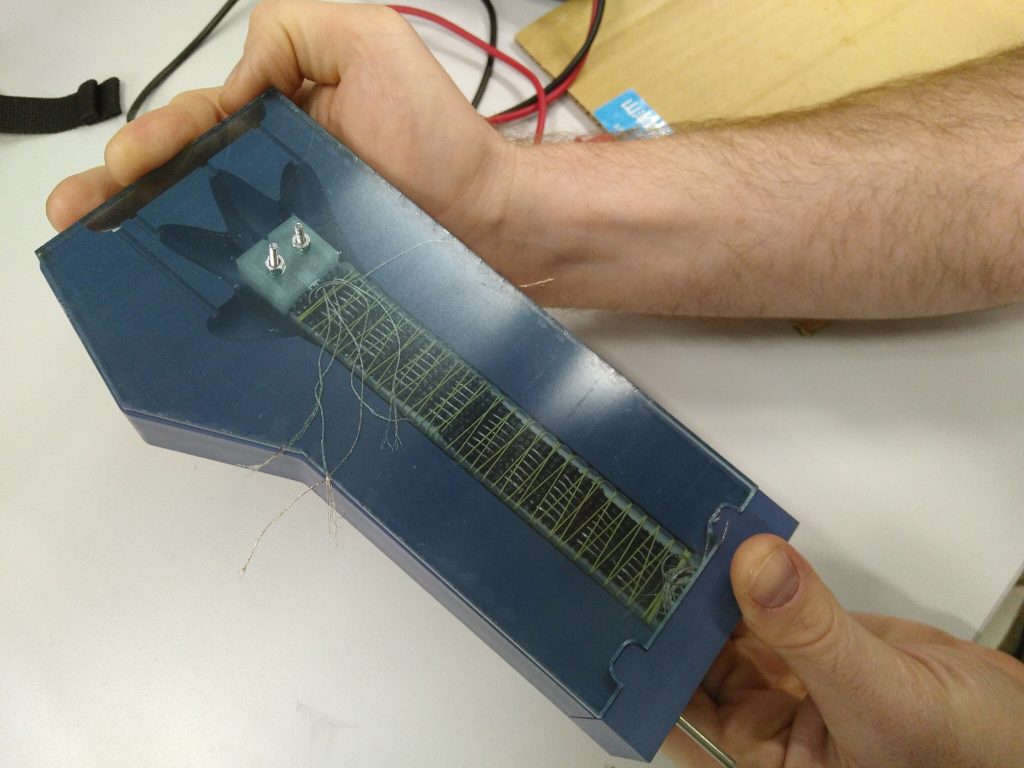

Step 2 mold containing the result of casting on the step 1 mold.

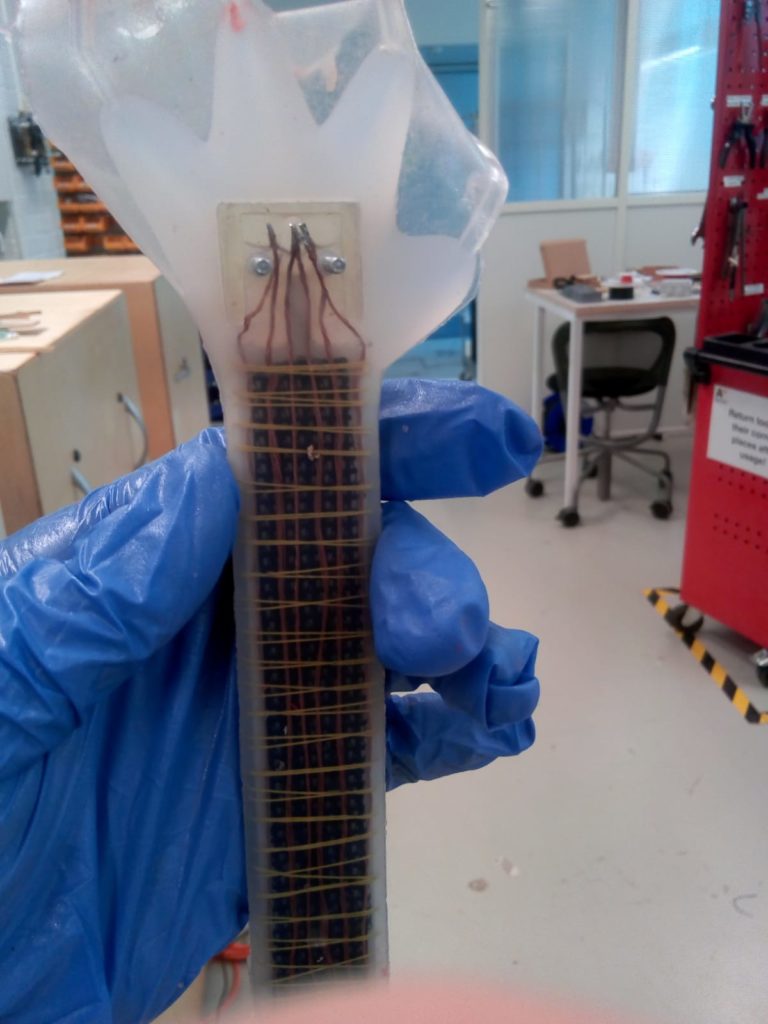

First try casting a hand. The chosen wiring oxidized fast.

Third casted pair of hands.